Quick Summary for Solar Light Buyers

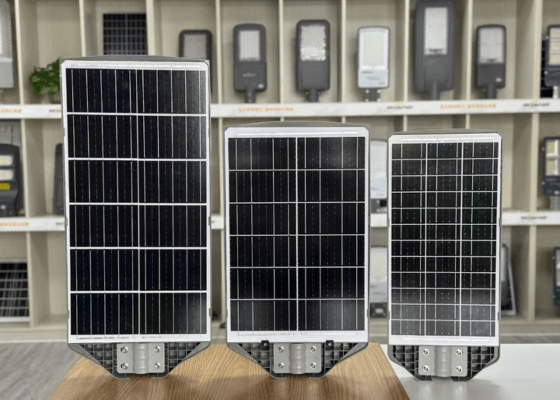

If you’re choosing solar panels for solar street lights or outdoor solar lighting systems, here’s the key difference: monocrystalline panels are more efficient and compact, ideal for tight pole-mounted applications. Polycrystalline panels are more affordable, and still reliable, especially for ground-mounted lights with more space.

So, if you’re unsure which type suits your solar lighting project — whether for public roads, parking lots, gardens, or commercial sites — this guide will break it all down with clarity.

Let’s start by understanding each panel type on its own before we compare them side by side.

Table of Contents

ToggleWhat Are Monocrystalline Solar Panels? (With Pros and Cons for Solar Lighting)

What Are They?

Monocrystalline panels are made from a single crystal of high-purity silicon. These panels are sliced into thin wafers, creating solar cells where all atoms are neatly aligned. This orderly structure helps electrons move more freely, making monocrystalline panels more efficient at converting sunlight into electricity.

This makes them the go-to choice for integrated solar lights and advanced lighting systems. Their uniform black appearance is also favored in visible installations.

Pros & Cons for Solar Lights

The biggest advantage of monocrystalline panels is their high efficiency. Because they can generate more power per square meter, they’re perfect for compact designs — such as pole-mounted solar street lights or all-in-one solar garden lights. They also perform well in low-light conditions and extreme heat, meaning better battery charging consistency across seasons. Over time, they degrade more slowly, offering stronger long-term output.

The downside is their cost. The process of creating pure silicon crystals is complex and energy-intensive, which raises the price of each panel. Additionally, while they are highly effective, producing them involves more material waste compared to polycrystalline panels.

What Are Polycrystalline Solar Panels? (With Pros and Cons for Solar Lighting)

What Are They?

Polycrystalline panels are made by melting silicon fragments together and pouring them into square molds. As they cool, multiple crystals form in each cell, resulting in a less uniform structure. This reduces efficiency slightly but simplifies the manufacturing process.

These panels are common in large-scale, budget-sensitive projects where space is not a constraint — such as solar lights along rural roads or wide-area ground-mounted systems.

Pros & Cons for Solar Lights

The main appeal of polycrystalline panels is their lower cost. They’re easier to produce and waste less silicon during manufacturing. For projects that involve hundreds or thousands of units — like rural development or municipal road lighting — this cost advantage can be significant.

However, polycrystalline panels take up more space for the same power output. They are slightly less efficient, especially in cloudy weather or high-heat environments. Visually, their blue, speckled surface stands out more, which may not be ideal for modern or commercial sites where aesthetics matter.

Overall, polycrystalline panels are reliable and cost-effective, especially in sunny locations with plenty of room for installation.

Monocrystalline vs. Polycrystalline Efficiency: Why It Matters for Solar Lights

In solar street lights, panel efficiency directly affects how much energy is harvested to charge the battery each day. Monocrystalline panels convert more sunlight into electricity in the same amount of space, which is crucial on compact pole-top installations.

Polycrystalline panels, while less efficient, can still power lights reliably — but they may need more surface area and perform slightly less in cloudy weather. For small or all-in-one solar lights, monocrystalline is usually the better fit.

Now that we’ve looked at the technical core, let’s move into a practical, side-by-side comparison of how these two types of panels perform across key factors.

Side-by-Side Comparison: Cost, Space, Aesthetics, and Durability

Before we go deeper, here’s how these two panel types compare specifically for solar lighting systems.

1. Cost (The Budget Factor for Solar Lighting Projects)

For large-scale solar street light procurement, cost is often a key driver. Polycrystalline panels offer a lower unit price, which can reduce your total project cost — especially in budget-conscious government or commercial installations.

But cost per panel isn’t everything. Monocrystalline panels produce more energy in a smaller footprint, which means fewer failures due to undercharging and better night-time performance, especially in cloudy or shaded conditions.

If reliability and long battery life matter more than initial savings, monocrystalline panels are often worth the extra investment.

2. Aesthetics (The Visual Factor for Urban or Residential Areas)

Monocrystalline panels look cleaner — black, sleek, and more modern. This matters when your solar lights are installed in front of commercial buildings, along premium residential streets, or in tourism zones.

Polycrystalline panels, with their bluish tone and crystal patterns, are more visible and may stand out more. They’re commonly used in rural or industrial areas where aesthetics are less critical.

So if your project involves parks, campuses, or urban centers, the clean appearance of monocrystalline panels can improve the visual harmony.

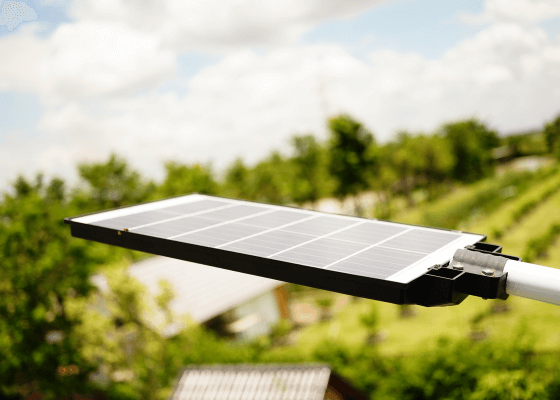

3. Space Efficiency (A Real Concern for Pole-Mounted Solar Lights)

Most solar street lights — especially integrated or all-in-one types — have limited space for the panel. This is where monocrystalline panels shine. Their higher efficiency allows you to use a smaller panel while still generating enough energy to charge the battery fully.

With polycrystalline, you’d need a larger panel to produce the same amount of power. That can be a challenge when trying to design compact, lightweight lighting systems.

In summary: for solar lights mounted high on poles, rooftops, or narrow posts, monocrystalline panels make the system more compact and efficient.

4. Temperature Performance & Lifespan (Crucial for Outdoor Solar Lights)

Solar lights often operate in harsh conditions — from desert heat to icy winters. Monocrystalline panels handle high temperatures better and degrade more slowly over time, ensuring your lights keep working efficiently year after year.

That means fewer maintenance cycles, fewer battery failures from undercharging, and better long-term savings. Polycrystalline panels still offer good durability, but they tend to lose performance faster in extreme heat.

For solar lights expected to run reliably for 5–10 years without intervention, monocrystalline gives you more confidence.

Let’s now look closer at each panel type and how they affect solar lighting systems on a technical and practical level.

How to Choose the Right Panel for Your Solar Lighting Project

Here’s a more detailed way to decide based on your project type and priorities:

Choose monocrystalline if your application involves:

- All-in-one solar street lights with integrated batteries and compact panel designs

- Urban or commercial areas where sleek appearance matters (e.g. downtown streets, shopping centers, office parks)

- Locations with frequent cloud cover or short daylight hours, where high efficiency is crucial for full battery charging

- High pole-mounted lights with limited surface area for panels (like highway lighting or security lighting)

- Premium residential zones, parks, or campuses where performance and aesthetics must go hand-in-hand

Monocrystalline is also recommended if you expect long-term usage (10+ years) and want to minimize performance decline, especially in regions with high heat or humidity.

Choose polycrystalline if your application includes:

- Large-scale rural road lighting, agricultural pathways, or perimeter lights for farms

- Ground-mounted solar lighting systems with flexible panel space (e.g. in remote villages, large properties, or mining camps)

- Budget-constrained public projects, such as municipality tenders where panel cost per watt is a key decision point

- Environments with stable sunlight and no shading, where the slightly lower efficiency won’t significantly impact daily battery charging

Polycrystalline is still a reliable choice for well-lit regions where space isn’t an issue and price is the top concern. It’s especially suitable for bulk procurement and government rollouts across wide, open landscapes.

The final decision depends on your project’s technical needs, physical environment, and financial goals. Understanding how your lights will be used — and where — is the smartest first step toward choosing the right solar panel type.

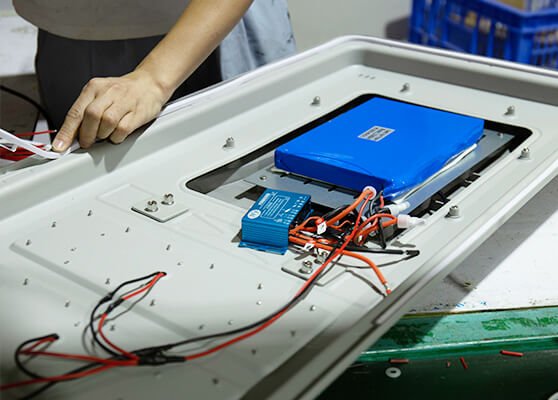

Other Crucial Factors: Batteries, Controllers, and Panel Quality

Aside from panel type, the solar controller, battery capacity, LED efficiency, and installation angle also play huge roles.

In 2025, many solar street lights now use monocrystalline panels with PERC or half-cut cell technology for even better energy capture. Paired with LiFePO4 batteries and MPPT controllers, these systems deliver consistent lighting even in tough environments.

Also, don’t forget: a poor-quality panel — regardless of mono or poly — can ruin the whole system. Always check for certifications, real test data, and experienced manufacturers.

FAQs About Choosing the Right Solar Panel for Street Lights

Is it okay to use polycrystalline panels in cloudy climates?

Yes, polycrystalline panels will still generate power on cloudy days, but their efficiency drops more noticeably compared to monocrystalline panels. In areas with frequent overcast skies or shorter daylight hours, this means your batteries may not charge fully every day. Monocrystalline panels handle diffuse light better, providing more stable performance in variable weather conditions, which helps ensure consistent lighting throughout the year.

Which panel charges the battery faster?

Monocrystalline panels generally charge batteries more quickly due to their higher energy conversion efficiency. This is especially important in early morning and late afternoon hours, when the light angle is low or during partly cloudy weather. Faster charging means the battery reaches full capacity earlier in the day, providing more runtime for the light and better reliability across seasons.

Can I replace a poly panel with a mono one on my solar light?

Yes, you can replace a polycrystalline panel with a monocrystalline one, but you must make sure the voltage and current ratings match your existing charge controller and battery system. Using a mismatched panel can cause charging inefficiencies or even damage components. It’s best to consult your supplier or installer before swapping panels to ensure safe and optimal system performance.

Which lasts longer in the field?

Both panel types are durable and designed for long-term use, typically 25–30 years. However, monocrystalline panels tend to degrade more slowly, especially in hot, humid, or corrosive environments like coastal areas. Over time, they retain a higher percentage of their original power output, which means more consistent performance with less maintenance.

Is there any visual benefit for public installations?

Absolutely. Monocrystalline panels have a sleek, uniform black appearance that integrates well with modern urban or commercial landscapes. This makes them ideal for parks, campuses, business districts, and other areas where visual harmony is important. Polycrystalline panels, with their blue, crystalline texture, can be more noticeable and may not match certain architectural styles as well.

Final Recommendation: Which Panel Type Is Right for You in 2025?

If your business installs or sources solar street lights or garden lighting systems, here’s our view:

Go with monocrystalline if you want maximum reliability, performance in all seasons, and compact designs. It’s the best long-term choice for cities, parking lots, or premium residential areas.

Choose polycrystalline for large-scale rural deployments, cost-sensitive contracts, or applications where space isn’t a limitation.

And remember — whichever panel you choose, make sure it’s backed by a good manufacturer, paired with the right battery, and designed for your site conditions. That’s the real formula for a solar lighting system that works for years to come.